According to the OIV (International Organisation of Vine and Wine), a wine is “dry” when after alcoholic fermentation its concentration of residual sugars is less than 4g/L. For most French red AOC wines, the concentration of fermentable sugars (glucose + fructose) must be less than 2 or even 3 g/L. Regarding the microbial stability of wine, it is nevertheless preferable to focus more precisely on glucose and fructose concentrations.

According to the OIV (International Organisation of Vine and Wine), a wine is “dry” when after alcoholic fermentation its concentration of residual sugars is less than 4g/L. For most French red AOC wines, the concentration of fermentable sugars (glucose + fructose) must be less than 2 or even 3 g/L. Regarding the microbial stability of wine, it is nevertheless preferable to focus more precisely on glucose and fructose concentrations.

In red winemaking, an alcoholic fermentation carried out at the end of the fermentation process results in almost total glucose depletion (<0.05 g/l) and low fructose levels (<0.3 g/l). It is considered that above 0.5 g/l glucose and fructose, the risk of Brettanomyces bruxellensis development is highly increased.

This information reminds us how much a successful vinification is the result of a succes

sion of details to anticipate and control. If we take the example of a must with a potential degree of 14% vol. i.e. with 240g/L of sugars. We realize that despite the transformation of 239g/L, the last gram is finally the most important to degrade but is also the most difficult!

In terms of image and to make a parallel with a sport that is dear to me, it would be like dropping the ball beyond the opposition try-line when scoring the winning try (…during the extra-time and against the All-Blacks in the World Cup final…).

Brettanomyces bruxellensis (responsible for the odours of horse sweat or gouache in wines) which frequently develops between the end of alcoholic fermentation and the beginning of malolactic fermentation finds in sugars and especially in glucose and fructose a first-choice development substrate.

To avoid promoting their growth and to give Saccharomyces cerevisiae yeasts every chance to “dry out” the must into fermentable sugars, it is preferable to respect the following points :

- Sort the berries to eliminate insufficiently ripe ones (because they remain whole during vinification and release sugars when the marc is pressed).

- To crush the grapes sufficiently to open the berries and limit late releases of sugars.

- Limit the competition of undesirable micro-organisms with different options that can be combined or not : S02, bioprotection with no-saccharomyces yeasts, addition of indigenous yeast pied de cuve or addition of active dry yeasts.

Concerning the realization of the indigenous yeast pied de cuve, I invite you to consult the article written on this subject HERE.

In the case of the addition of an active dry yeast, care must be taken to choose it carefully! It is advisable to use a yeast with high fermentation capacity, fast implantation ability, fermenting regularly and transforming all fermentable sugars, while producing little volatile acidity. It appears that not all strains have the same abilities in these respects (illustrated by the data mentioned in graphs 1 and 2).

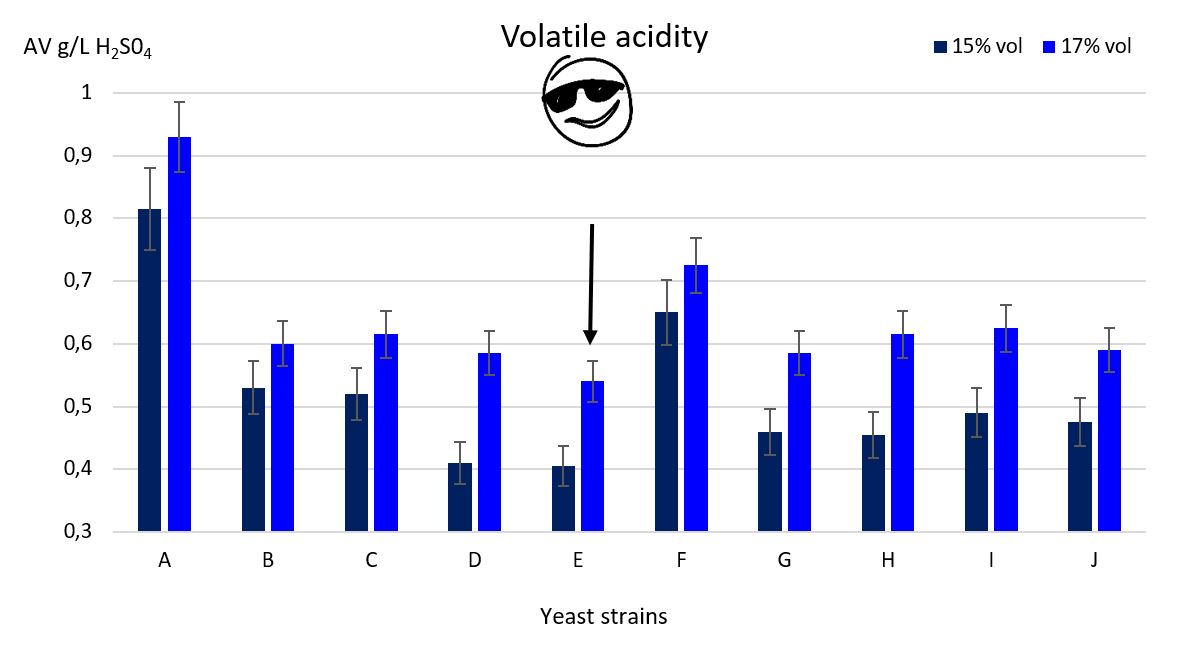

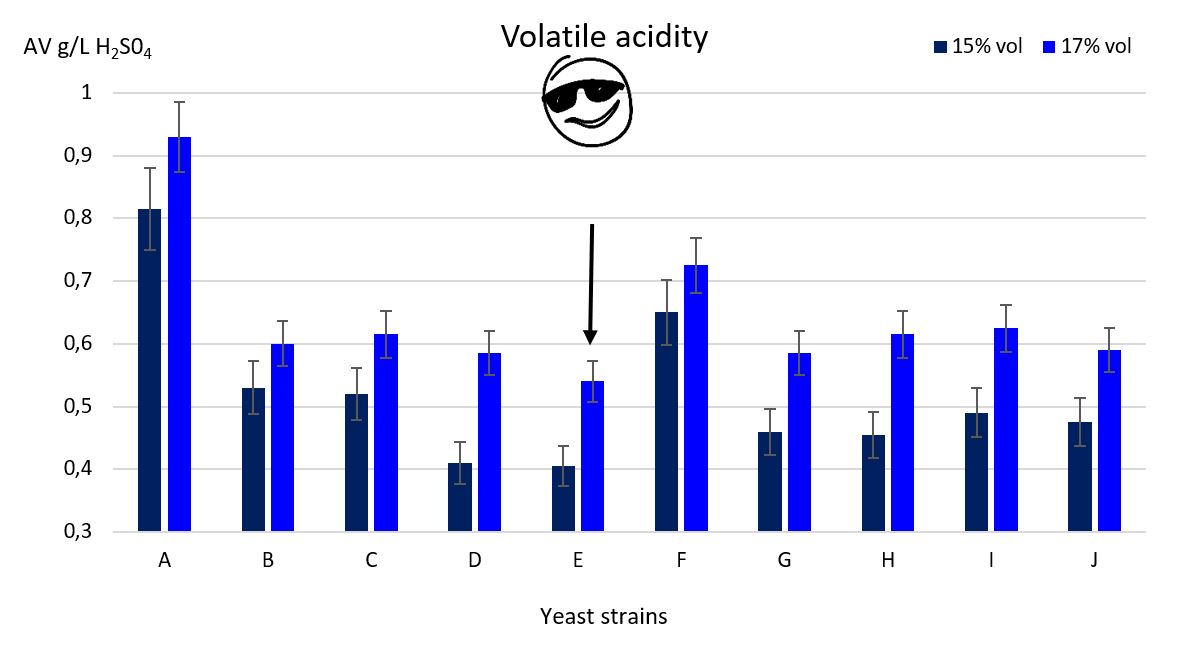

Comparison of 10 strains of active dry yeast identified as the most fermenting strains on the oenological market worldwide. Average data from 2 repetitions per modality. Fermentation of red grape must with 15 and 17% potential alcohol vol., after enrichment in sugar before starting the AF.

Graph n°1 : Glucose + Fructose values in g/L, at the end of AF.

At 15% potential vol., only 1 strain is not capable to degrade all sugars. At 17% vol, only the E strain can meet the “anti-brett” specifications, i.e. with a fermentable sugar concentration of less than 0.5 g/L.

Graph n°2 : volatile acidity values in g/L expressed in H2S04, at the end of AF.

If we look at the volatile acidity produced by these same yeast strains, we realize that the E strain that has degraded the most sugars is the one that produces the least at 15 and 17% potential alcohol vol. The differences between strains are huge, ranging from 0.4 to 0.9 g/L expressed as H2S04.

- Control yeast nutrition : neither too much (230 mg/L maximum assimilable nitrogen), nor too little (140 mg/L minimum). To be adapted according to the conditions.

- Provide oxygen to the yeasts to promote membrane fluidity at the end of fermentation.

- Temperature management :

- avoid thermal shock when adding yeast starter

- do not exceed 28°C in the heart of the marc

- Isolate the press wines until the glucose-fructose concentrations of free-run wines and press wines are checked separately. If the press wines contain too much sugar, wait until they are completely depleted of fermentable sugars before blending them.

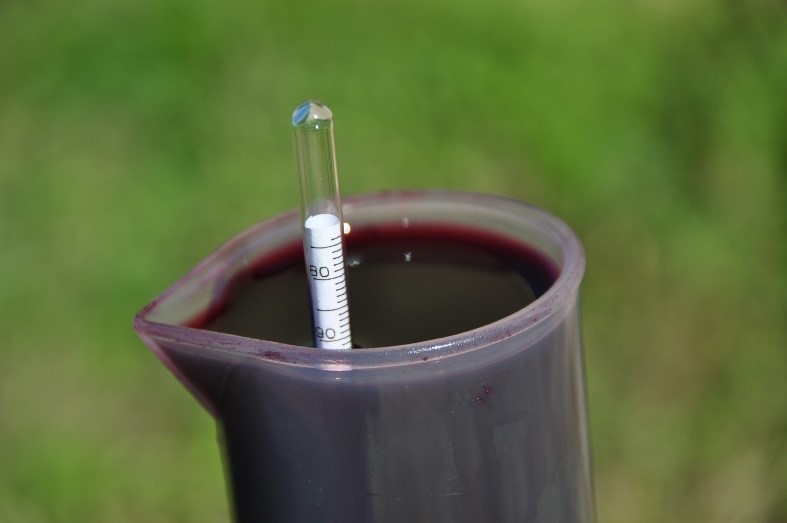

Practical advice : do not rely on the mustimeter to evaluate the end of fermentation because, depending on the wine matrix, densities ranging from 0.996 to 0.991 can result in glucose + fructose concentrations below 0.2 g/L in both cases. Do a laboratory assay as soon as the density seems to stop moving.

Practical advice : do not rely on the mustimeter to evaluate the end of fermentation because, depending on the wine matrix, densities ranging from 0.996 to 0.991 can result in glucose + fructose concentrations below 0.2 g/L in both cases. Do a laboratory assay as soon as the density seems to stop moving.

According to the OIV (International Organisation of Vine and Wine), a wine is “dry” when after alcoholic fermentation its

concentration of residual sugars is less than 4g/L. For most French red AOC wines, the concentration of fermentable sugars (glucose + fructose) must be less than 2 or even 3 g/L. Regarding the microbial stability of wine, it is nevertheless preferable to focus more precisely on glucose and fructose concentrations.

In red winemaking, an alcoholic fermentation carried out at the end of the fermentation process results in almost total glucose depletion (<0.05 g/l) and low fructose levels (<0.3 g/l). It is considered that above 0.5 g/l glucose and fructose, the risk of Brettanomyces bruxellensis development is highly increased.

This information reminds us how much a successful vinification is the result of a succession of details to anticipate and control. If we take the example of a must with a potential degree of 14% vol. i.e. with 240g/L of sugars. We realize that despite the transformation of 239g/L, the last gram is finally the most important to degrade but is also the most difficult!

In terms of image and to make a parallel with a sport that is dear to me, it would be like dropping the ball beyond the opposition try-line when scoring the winning try (…during the extra-time and against the All-Blacks in the World Cup final…).

Brettanomyces bruxellensis (responsible for the odours of horse sweat or gouache in wines) which frequently develops between the end of alcoholic fermentation and the beginning of malolactic fermentation finds in sugars and especially in glucose and fructose a first-choice development substrate.

To avoid promoting their growth and to give Saccharomyces cerevisiae yeasts every chance to “dry out” the must into fermentable sugars, it is preferable to respect the following points :

- Sort the berries to eliminate insufficiently ripe ones (because they remain whole during vinification and release sugars when the marc is pressed).

- To crush the grapes sufficiently to open the berries and limit late releases of sugars.

- Limit the competition of undesirable micro-organisms with different options that can be combined or not: S02, bioprotection with no-saccharomyces yeasts, addition of indigenous yeast pied de cuve or addition of active dry yeasts.

Concerning the realization of the indigenous yeast pied de cuve, I invite you to consult the article written on this subject HERE.

In the case of the addition of an active dry yeast, care must be taken to choose it carefully! It is advisable to use a yeast with high fermentation capacity, fast implantation ability, fermenting regularly and transforming all fermentable sugars, while producing little volatile acidity. It appears that not all strains have the same abilities in these respects (illustrated by the data mentioned in graphs 1 and 2).

Comparison of 10 strains of active dry yeast identified as the most fermenting strains on the oenological market worldwide. Average data from 2 repetitions per modality. Fermentation of red grape must with 15 and 17% potential alcohol vol., after enrichment in sugar before starting the AF.

Graph n°1 : Glucose + Fructose values in g/L, at the end of AF.

At 15% potential vol., only 1 strain is not capable to degrade all sugars. At 17% vol, only the E strain can meet the “anti-brett” specifications, i.e. with a fermentable sugar concentration of less than 0.5 g/L.

Graph n°2 : volatile acidity values in g/L expressed in H2S04, at the end of AF.

If we look at the volatile acidity produced by these same yeast strains, we realize that the E strain that has degraded the most sugars is the one that produces the least at 15 and 17% potential alcohol vol. The differences between strains are huge, ranging from 0.4 to 0.9 g/L expressed as H2S04.

- Control yeast nutrition : neither too much (230 mg/L maximum assimilable nitrogen), nor too little (140 mg/L minimum). To be adapted according to the conditions.

- Provide oxygen to the yeasts to promote membrane fluidity at the end of fermentation.

- Temperature management :

- avoid thermal shock when adding yeast starter

- do not exceed 28°C in the heart of the marc

- Isolate the press wines until the glucose-fructose concentrations of free-run wines and press wines are checked separately. If the press wines contain too much sugar, wait until they are completely depleted of fermentable sugars before blending them.

Practical advice : do not rely on the mustimeter to evaluate the end of fermentation because, depending on the wine matrix, densities ranging from 0.996 to 0.991 can result in glucose + fructose concentrations below 0.2 g/L in both cases. Do a laboratory assay as soon as the density seems to stop moving.

Practical advice : do not rely on the mustimeter to evaluate the end of fermentation because, depending on the wine matrix, densities ranging from 0.996 to 0.991 can result in glucose + fructose concentrations below 0.2 g/L in both cases. Do a laboratory assay as soon as the density seems to stop moving.